|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

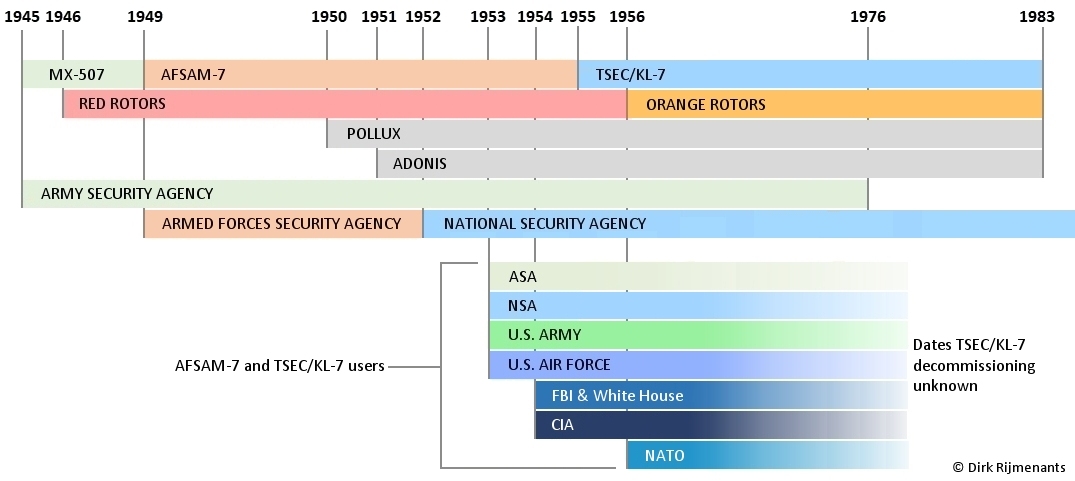

The TSEC/KL-7 is an

American offline crypto machine, developed by the

Army Security Agency (ASA) and Armed Forces

Security Agency (AFSA) under the name AFSAM-7. In

1953, the machine was introduced by its

successor, the National Security Agency (NSA) and

in 1955 renamed TSEC/KL-7. It was the first

lightweight tactical rotor crypto machine using

electronics, initially developed as standard

crypto device for the U.S. military, CIA and FBI,

and later the military and state departments of

all NATO members and some Asian countries, until

the mid-1960s. The KL-7 later served mostly as

backup, often superenciphered on other

cryptosystems, until its withdrawal from service

in 1983.

The KL-7 was a 1950s marvel of technology that combined the latest cryptologic knowledge and electronics. The cleverly designed keyboard changes the signal direction through the rotors, notch rings on the rotors control the rotor movement in a most complex fashion, and electron tubes control the timing signals for the printer. The KL-7 had excellent cryptographic properties and was designed to resist any cryptanalytic attack by the Soviets, even if the technical details were compromised. Two serious security breaches occurred in the 1960s, when U.S. Army Signals Warrant Officer Joseph Helmich and Navy Chief Warrant Officer John Walker independently compromised the KL-7 and KL-47. They sold the technical repair and maintenance manuals and secret operational key lists to the Soviets, allowing them to decrypt U.S. Navy communications, and message trafic in the Southeast Asian conflict areas. The history of the KL-7 and its

technical specifications were kept secret for

decades, and information about the machine only

gradually surfaced in recent years. This page is

a tribute to the ASA, AFSA, and NSA cryptologists

and engineers who developed the KL-7, as well as

the men who operated the machine while serving

their country around the world. You can also

download an accurate TSEC/KL-7 simulator to

experience the machine first-hand. |

|

A call

to former KL-7 and KL-47 operators, technicians,

and related signals associations and

organizations. Help us preserve cyptologic

history by sharing your personal experience with

the KL-7 or KL-47, its use in the field during

exercises or operations, and the pros and cons.

The machine is declassified, and we're not

interested in classified information. Please contact us to document your story, or spread this

call. More info on our Crypto News. |

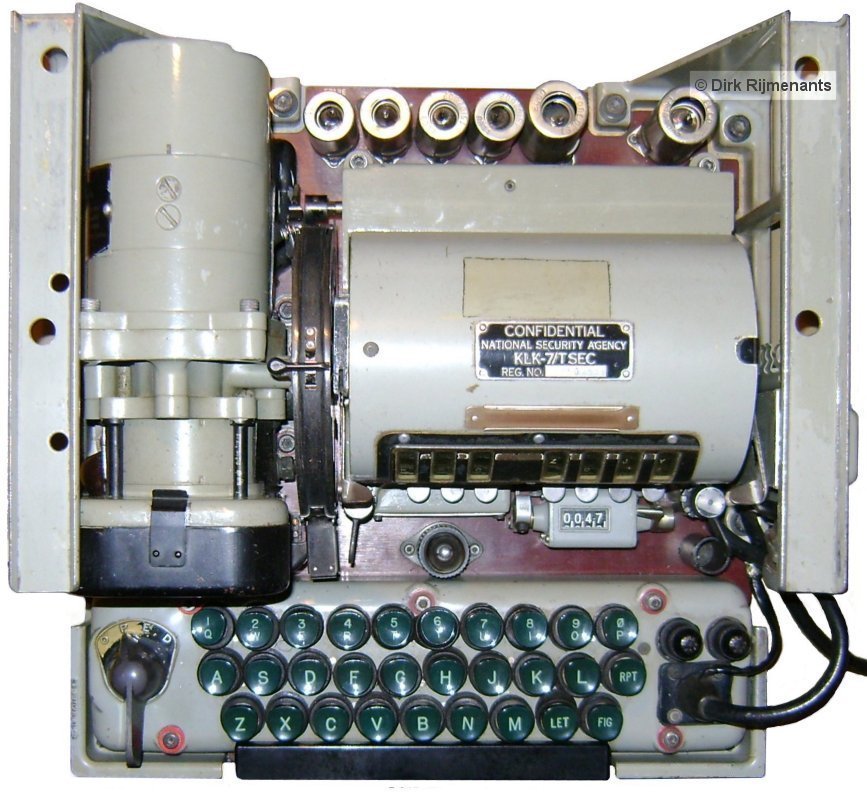

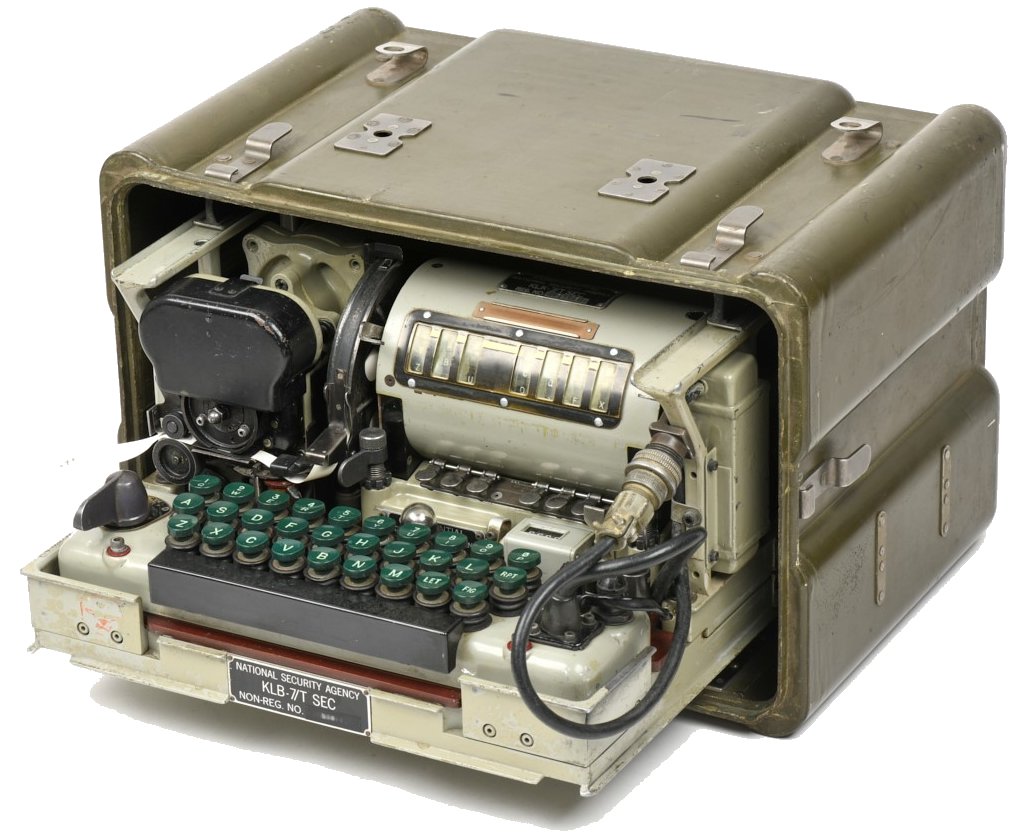

General Description

The TSEC/KL-7 is an

offline non-reciprocal rotor cipher machine with

electro-mechanical and electronic components,

including electron

tubes. The machine

measures 12 x 12 x 6.37 inches (30.5 x 30.5 x

16.2 cm) and weighs a mere 20.5 lbs (9.3 kg). The

KL-7 operates on 24 volts DC to power the motor-generator (DC motor drives an AC generator).

Electrical properties:

The 24 volts to power the KL-7 could either come from batteries, as available in vehicles, or from the mains. For use on mains there is a separate AC power converter that can be set to 100-125 V or 200-250 V at 50-60 Hz, and its transformer with rectifier delivers 21 to 31V DC to the KL-7. The batteries or AC power converter output are attached to the connector of the 24 volts power cord, located at the front-right of the machine (see also electronics section). In 1955, the AFSAM-7 was

renamed TSEC/KL-7, following NSA's nomenclature.

TSEC stands for Telecommunications Security

(COMSEC), K for Crypto equipment and L for

Literal because the encrypted output is in

letters (A through Z). For components of a

machine, the TSEC comes after the item

designation. Below the NSA naming of the main

KL-7 parts, followed by the AFSA naming from its

predecessor agency. See also NSA nomenclature table

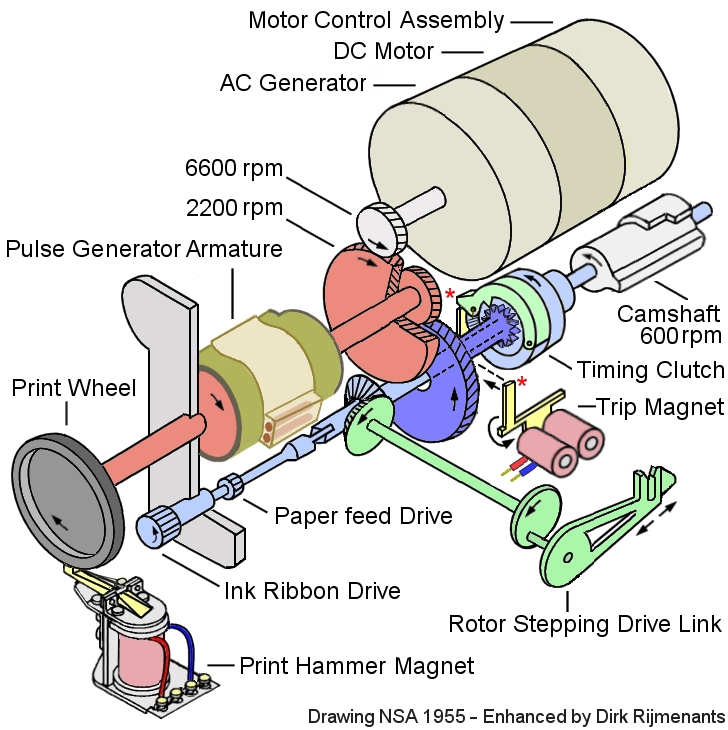

The

other important parts are the mode selector and

sliding contact board

underneath keyboard to switch the signals through

the rotors and select the different cipher modes,

the set

of rotors to perform

the encipherment and notch rings to control their

movement, the pulse generator,

the timing

unit, and one 12AX7

double triode vacuum electron tube and three 2D21 thyratron xenon gas-filled

tubes provide the

timing signals for the printer,

which prints the text or code groups on a gummed

paper tape.

|

|

||||||||||||||||

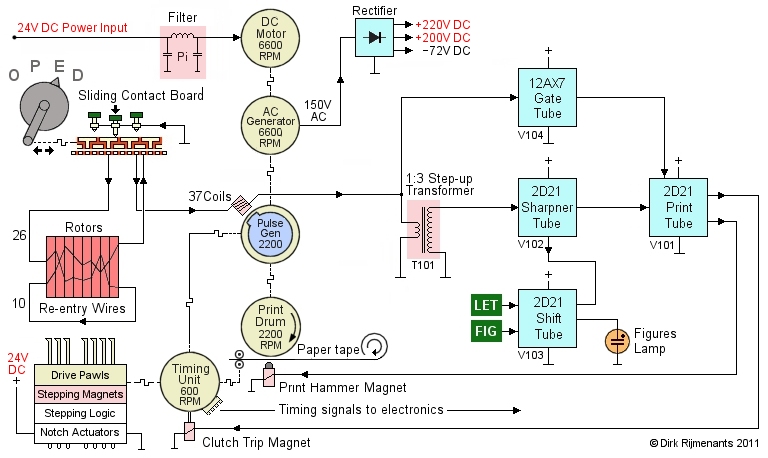

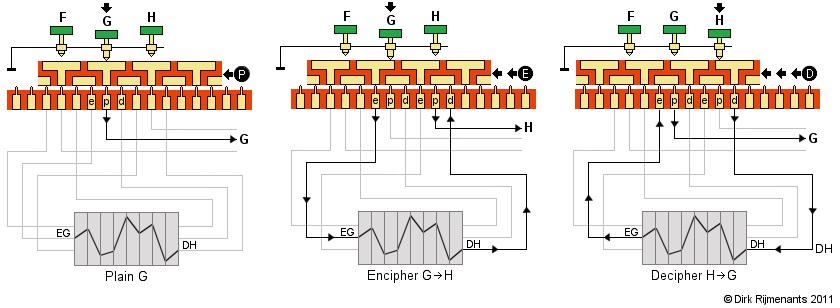

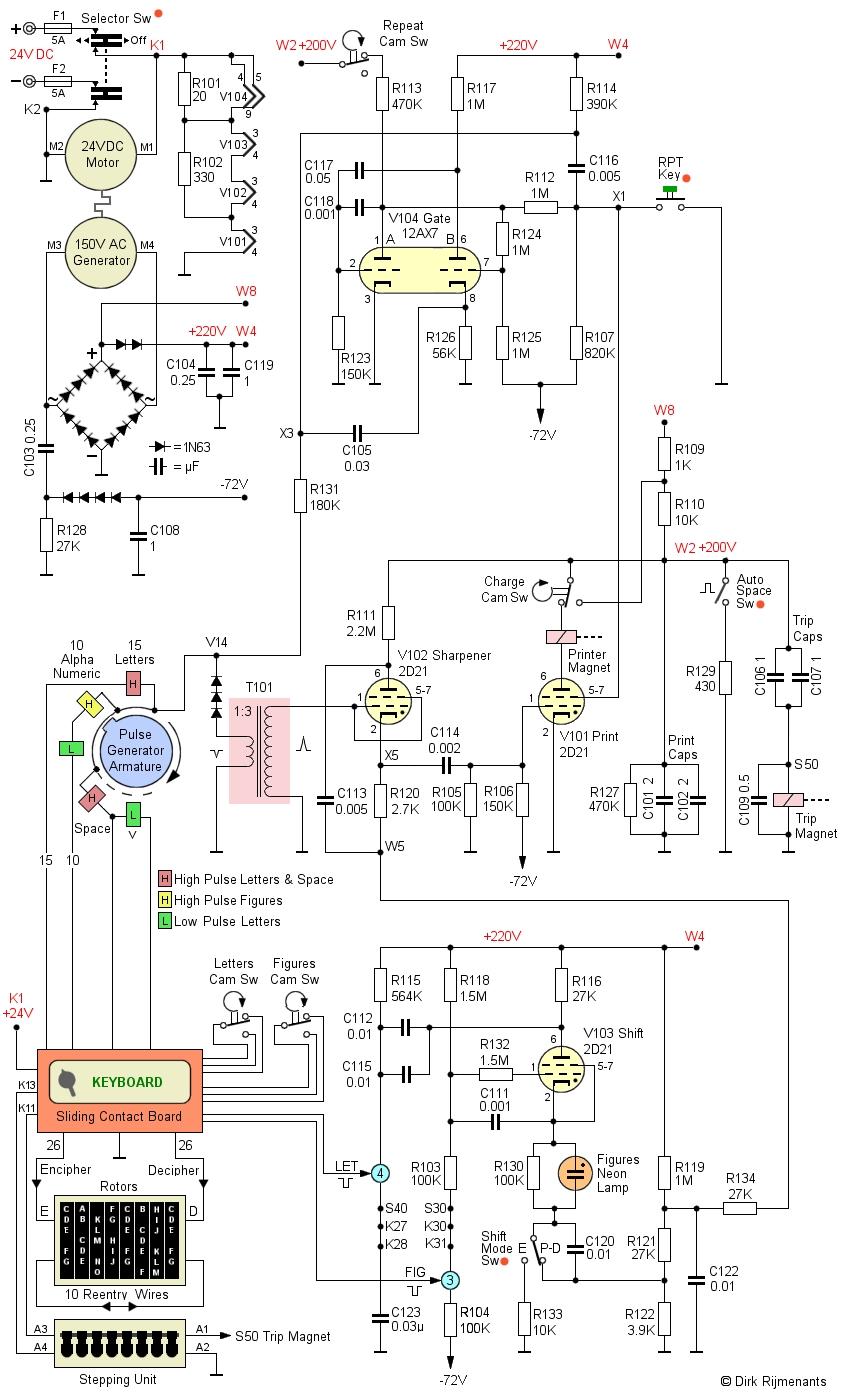

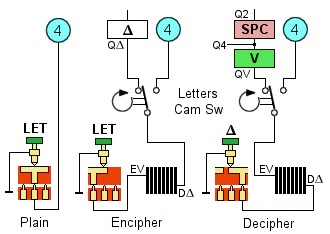

General Schematic

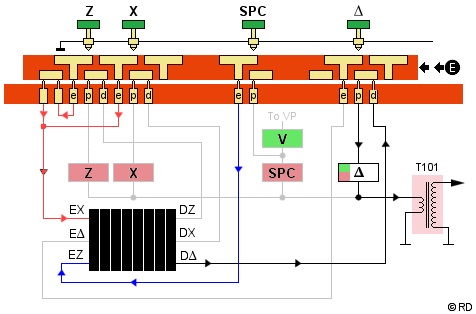

* Depressing a key will ground one of the pulse coils. The rotors encipher that signal on its way to the pulse generator. The encipherment is non-reciprocal and the sliding contact board must therefore switch the direction of the signal through the rotors, to select between enciphering and deciphering. When the armature of the pulse generator passes a grounded coil, that coil induces a pulse, which is passed to the Step-up Transformer, and also switches the Gate tube, which in turn enables the Print tube to receive the print pulse.

The transformer sends the pulse to the Sharpener tube, which cleans up the signal and sends it to the Print tube that activates the print hammer. However, if the Shift tube is in FIG mode, it tells the Sharpener tube to only accept high pulses from figure coils and ignore any low pulse from letter coils. The Print tube also activates the timing unit clutch, causing the timing unit to perform one single cycle in 0.1 seconds (600 rpm). This cycle controls four cam switches with timing signals for the letters and figures function, the print control circuit, and to prevent multiple cycling.

During the printing

cycle, one timing unit cam switch resets the Gate tube, which in turn

disables the Print tube, to prevent the

processing of unwanted double or stray keyboard

pulses before the rotor stepping is completed and

the machine is ready to process a new keyboard

pulse.

The notch rings on the rotors are sensed by actuator

switches of the stepping logic

that activates some of the stepping magnets.

These magnets enable drive pawls, and the timing

unit provides mechanical power to the drive pawls

to move the rotors. More details and the complete

circuitry are found in the electronics

section. |

|

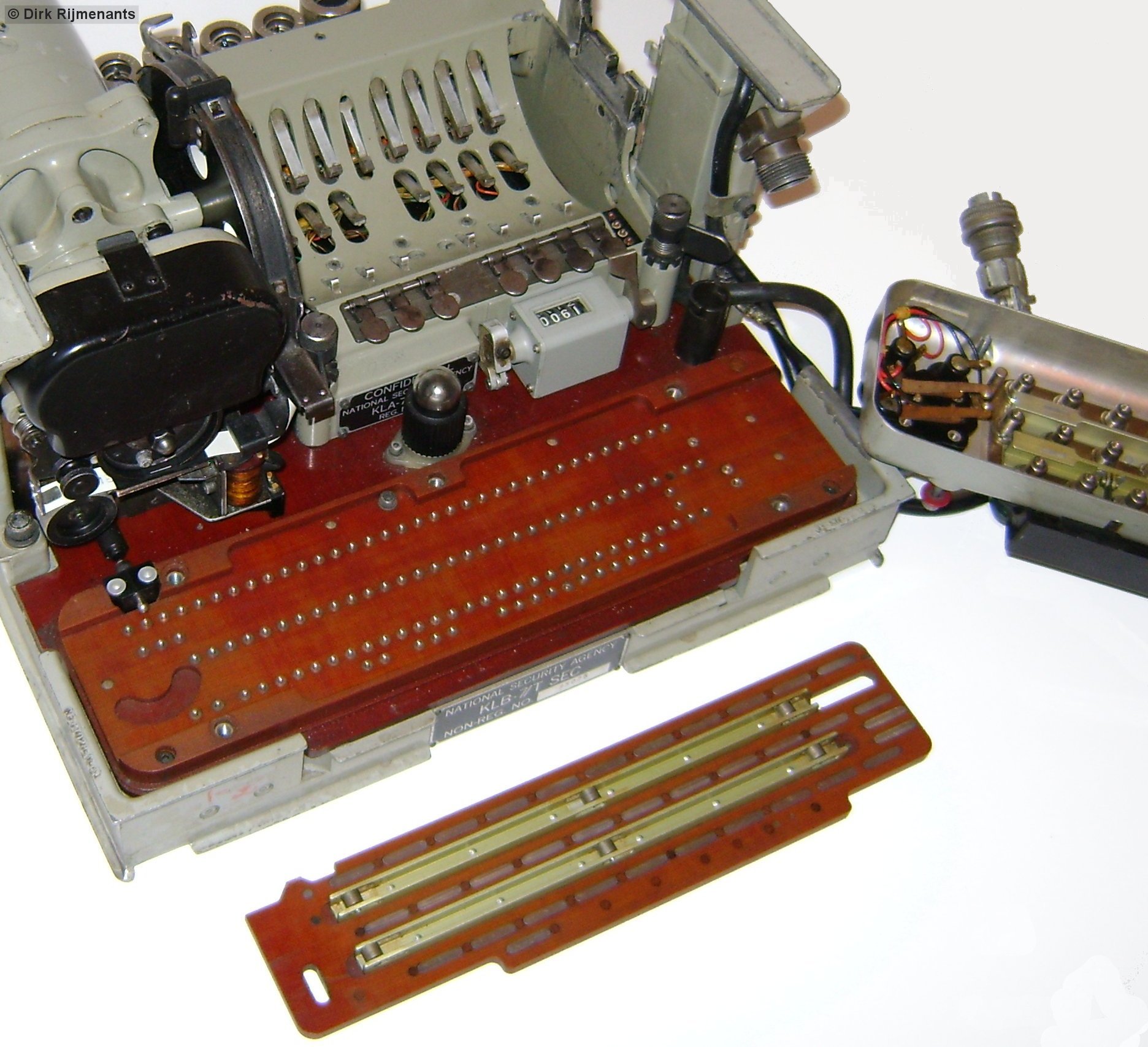

Mode Selector and Sliding Contact Board

The Contact Panel

Assembly comprises spring-loaded contacts across

the bottom plate that mate with contacts at the

bottom of the keyboard, stepping unit and printer. This

modular design allows easy disassembly of all

main parts of the KL-7 for maintenance and

repair.

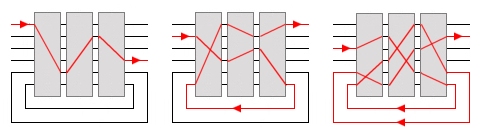

To switch between enciphering and deciphering, the KL-7 has a simple and compact solution to change the direction of the signals through the rotors. The keyboard contains a large Sliding Contact Board which is operated by the Selector handle with the positions O-P-E-D (Off - Plain - Encipher - Decipher). The sliding contact board with its T-shaped contacts moves from right to left between the keyboard keys and the spring-loaded contacts on the contact panel assembly. The keys are all grounded and depressing them will ground the T-shaped contact plate at the top of the sliding contact board. The selector handle has a pawl that grasps into a vertical slot on the left of the contact board. Turning the selector clockwise moves the sliding contact board from right to left. Two rails on the sliding contact board press it down onto the spring-loaded pins, meanwhile ensuring smooth movement of the contact board. The sliding contact board also contains the main power switch. The KL-7 power cable with connector (on the right) passes the radio interference filter (vertical block right-side machine), enters at the right-side top of the keyboard (see flipped keyboard) and connects to two slide contacts that touch two copper stripes (double-T contacts) at the far right of the contact board. The board also switches various parts of the electronics. |

|

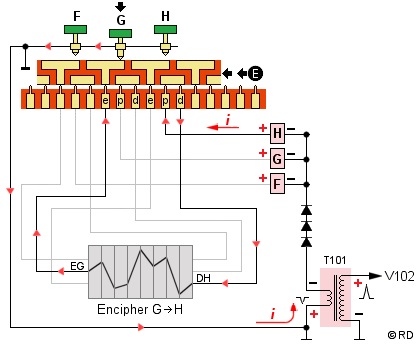

In Encipher mode, the depressed G key is connected via the T-shape and its GE contact to the EG (Encipher letter G) contact on the left side of the cipher unit that holds the rotors, exits at the DH (Decipher H) contact on the right side, passes the small connecting bar of the H key and continues from its Print contact to the H pulse coil.

In Decipher mode, the depressed H key is connected via the T-shape and its HD contact to the DH (Decipher letter H) contact on the right side of the cipher unit, exits at the EG (Decipher G) contact on the left side, passes the connecting bar of the G key, and continues from its Print contact to the G pulse coil.

The use of two neighboring T-shapes for each key enables the O-P-E-D sequence from right to left. The above is a simplified example with 3-pin rotors. In reality, the KL-7 uses 36-pin rotors. Note that, to perform the piggyback functions, some E, P and D connections from “J”, “V”, “X”, “Y”, “Z”, SPACE, FIG and LET are swapped, and additional contacts on the sliding contact board switch some piggyback wires and other control functions.

Important note on direction of current!

The arrows in the above image are only used to easily

visualize how the keys are connected to the pulse coils. In reality, the current travels in the

opposite direction! Each pulse coil generates its own

current when the armature of the pulse generator passes

that coil. The positive side of the coil is connected

through the key contacts and rotors to the common.

However, this is not actual "grounding" of the

signal in the usual sense.

Important note on direction of current!

The arrows in the above image are only used to easily

visualize how the keys are connected to the pulse coils. In reality, the current travels in the

opposite direction! Each pulse coil generates its own

current when the armature of the pulse generator passes

that coil. The positive side of the coil is connected

through the key contacts and rotors to the common.

However, this is not actual "grounding" of the

signal in the usual sense.

A pulse coil only uses the common to transport its signal to the step-up transformer, which inverts the signal before it is processed by the electronics. Within the circuit, each pulse coil can be considered as a separate power source with its own circuit.

When a key is depressed, and depending on the Selector position, the positive side of the coil that represents its enciphered or deciphered version is connected to the general common. When energized, the coil sends its positive signal through the "common" and the step-up transformer (in opposite polarity) to end its route at the negative side of the same coil (see red arrows). See also the complete electronic circuit and timing signals.

How can depressing key G, connected to EG on the left of the rotor pack, ground the correct coil to print the encrypted letter H? For a given position and wiring of the rotors, when EG is connected to DH, then DH is also connected to EG. In fact, to encrypt the letter G, the KL-7 does not "encrypt" the letter G but grounds the letter G, and by doing so, the rotor pack grounds its counterpart DH, which is connected to the H coil that is energized by the pulse generator and sends the signal to print the letter H.

Since EG and DH are reciprocal, this works also for decryption. However, this is only true for this particular position of the rotors, which changes after each letter of the message. This is what makes the KL-7's sliding contact board so clever. This is also why in the first example the black arrows are opposite to the actual direction of the current, because following the path, starting from the H coil, seems illogical when you must first depress key G.

The sliding contact board also switches some additional functions in the electronic circuit. Also, depending on the selected mode, the signal from some keys, involved in the piggyback system, is rerouted. The board also has a notched part in front of the printer mechanism. With the mode selector in Encipher position, this cam pushes a pin into the printer mechanism, causing the KL-7 to print a space after each fifth character, the standard format for cryptograms.

* Note on contact problems. Passing the signal from a depressed key to a pulse coil requires many contact points to work flawlessly (a contact point is where two switching or sliding contacts make contact). In Plain mode, there are only two contact points: key to sliding contact board and from there to contact panel assembly p contact, connected directly to the pulse coil. In Encipher or Decipher mode, there are 13 contact points: one from key to sliding contact board, one to contact panel assembly, 9 through the rotors, and two contacts on the sliding contact board's small bridge, connected to the pulse coil.

However, for each time that the signal exits the rotor cage at one of the re-entry contacts, an additional pass through the rotors adds 9 contact points to the signal path. Theoretically, up to 10 additional passes are possible, thus adding 90 additional contact points. Also, using the LET or FIG key in Encipher or Decipher mode will add two additional contact points on the Letters Cam switch or Figures Cam Switch. In any mode, one single failing contact will prevent the machine from processing the character and stepping the rotors to process the next letter. This is the notorious so-called dead-rove, usually caused by poor maintenance. Regular and thorough cleaning of the rotors and keyboard contacts was therefore essential.

There are 324 contact points between the eight rotors mutually, and the rotor contact plates from the cipher unit. Between the keyboard and the top of the sliding contact board are 29 contact points (letter keys, FIG, LET and SPACE). Between the bottom of the sliding contact board and the top of the contact panel assembly are 119 contact points. In total, 472 contact points move (rotors, sliding contact board) or switch (keyboard keys). This does not take into account the numerous contacts between the bottom of the modular parts (motor-generator, pulse generator, stepping unit) and the top of the contact panel assembly. These are less prone to dirt because the modular parts are fixed onto the contact panel assembly and are only removed when a module is defective or requires maintenance. The only exception is the cipher unit, removed daily to load the new rotor settings.

TSEC/HL-1 Tape Reader and KLX-7 Keyboard Adapter

An optional TSEC/HL-1

Tape Reader was available for the KL-7. In NSA

nomenclature, the H means ancillary device that

helps processing, and L means letters output. The

HL-1 reads 5-bit punched tapes with plain or

ciphertext and sends it to the KL-7. This enables

fast processing of message tapes, received from,

or created on a standard teleprinter, avoiding

the laborious manual typing of messages on the

KL-7.

The use of the HL-1 tape reader requires the KLX-7/TSEC Keyboard Adapter, mounted between the keyboard and the Sliding Contact Board. The installation of the KLX-7 therefore requires the removal of the KL-7 keyboard cover. To install the KLX-7, the Mode Selector must be in Decipher position. The five screws of the keyboard are removed, the keyboard is lifted without moving the Sliding Contact Board, and the standoffs are removed. The KLX-7 is placed on the contact panel while ensuring its Selector handle extension engages in the notch of the Sliding Contact Board. The KLX-7 is then fixed with screws in its five hex nuts. Finally, five standoffs are placed in the hex nuts, and the keyboard is fixed back onto the chassis by tightening its screws into the standoffs. Once the KLX-7 is installed, its connector is located at the center front, just underneath the KL-7 keyboard. The KLX-7 board has 30 pressure contacts with their caps through the upper part of the board. Each of these contacts is connected to the KLX-7 connector. Also, two contacts connect the two sliding 24 volts power contacts from the KL-7 to the KLX-7 connector to pass the 24 volts to the HL-1. Moreover, depending the KL-7 Mode Selector position, a 24 volts signal is sent to the HL-1 to either process letters, figures and spaces in Plain and Encipher mode, or only letters in Decipher mode, and ignore all other 5-bit characters on the tape. The HL-1 Tape Reader senses 5-bit punched tape and converts the bits, through a series of relays, into connecting the common to one of the 26 letters, space, LET or FIG wire, and passes that common through the adapter cable to the KLX-7 adapter underneath the keyboard. This has the same effect on the KL-7 as depressing the keyboard key and grounding its corresponding pulse coil(s).

Note

on drawing: In reality, the TSEC/HL-1 is as wide

as the KL-7, and the connector on the HL-1 side

is about twice the size of the connector on the

KLX-7 side. The connector also has an alligator

clip for grounding. Before 3-wire sockets became

standard, this clip was fixed onto some metal

part near the socket. More on the HL-1 tape

reader at Jerry Proc's

Crypto Machines |

|

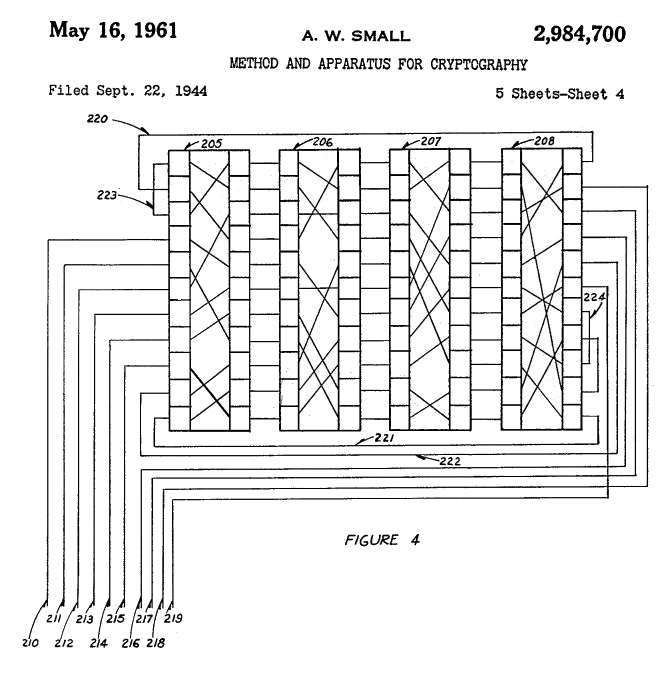

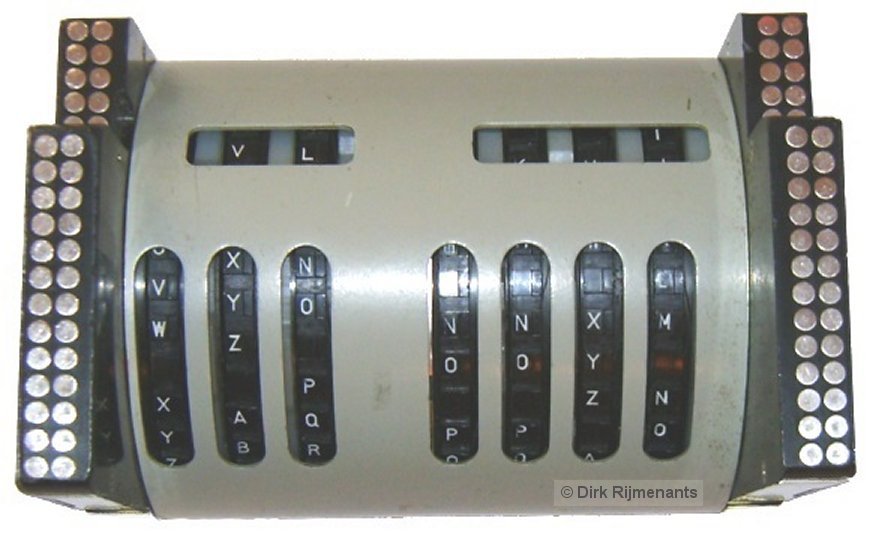

The Rotors and Notch Rings

The enciphering in the KL-7 is performed by

eight rotors. These are set according to the key list. Each individual rotor performs a substitution

cipher. The rotor core wiring is still classified, and

most surviving rotors are either stripped of their

wirings or inaccessible.

The enciphering in the KL-7 is performed by

eight rotors. These are set according to the key list. Each individual rotor performs a substitution

cipher. The rotor core wiring is still classified, and

most surviving rotors are either stripped of their

wirings or inaccessible.

Its wiring was also changed on a regular basis, in contrast to, for instance, the German Enigma where the wiring never changed during its whole service time (the U.S. cryptologists learned the lessons). The KL-7 rotors were easily rewired manually by simply plugging the contacts into other positions without the need of soldering. These were designated by NSA as Red Rotors. Due to persisting problems, these were replaced by the Orange Rotors in 1956.

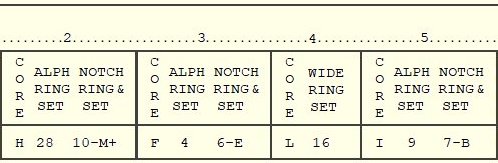

The KL-7 had a set of 12 rotors to choose from, later expanded to 13, labelled "A" through "M". (see CORE on part of the key list on the right). Each rotor core has 36 flat contacts on the left side (as seen in cipher unit windows) that are wired in a scrambled fashion with 36 spring-loaded contacts on the right side. The wiring performs a substitution encipherment. An adjustable black alphabet ring is attached to the rotor core. These letters are visible through the little windows of the cipher unit. The drive-pawls from the rotor stepping unit use the notches on the alphabet ring to advance the rotors.

The side of the alphabet ring is also marked with the numbers 1 through 36. By depressing the alphabet ring, it can rotate relative to the rotor core wirings. This is done by aligning an alphabet ring number with the white arrow on the side on the rotor (ALPHA RING SET). The 36 positions on all alphabet rings are labelled as shown in the table below. Note that 10 of the positions on the alphabet ring are left blank.

| Rotor Labels | A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | P | Q | R | S | T | U | V | W | X | Y | Z | ||||||||||

| Numbers aside | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 | 27 | 28 | 29 | 30 | 31 | 32 | 33 | 34 | 35 | 36 |

The KL-7 also has a set

of 11 white plastic notch rings. The notches and

cams on these rings control seven stepping

switches in the rotor stepping unit. They are responsible for the highly

irregular movement of the rotors. These notch

rings were also part of the key settings.

The notch rings are labelled 1 through 11 on their side, at the right of a little black arrow (NOTCH RING & SET number). The notch rings are attached to any of the rotor cores by aligning the black arrow of the notch ring with the little hole near the edge of the rotor, then depress and align the notch ring with the required letter on the alphabet ring (NOTCH RING & SET letter). Since there are some blanks on the alphabet ring, these positions are marked on the key list as the letter on its left with plus sign (e.g. position 18 is M+). As part of the key settings, a selection of seven notch rings is attached to the seven moving rotors. The stationary non-moving rotor, at the fourth position in the cipher unit, must always carry the special wide ring and is aligned according to the key list (WIDE RING SET). The rotors had persistent contact problems, caused by particles from the beryllium copper contacts that wore off and turned into non-conductive abrasive copper oxide. The beryllium copper dust particles are toxic and inhaling these should be strictly avoided. More on the rotors in the development section. |

|

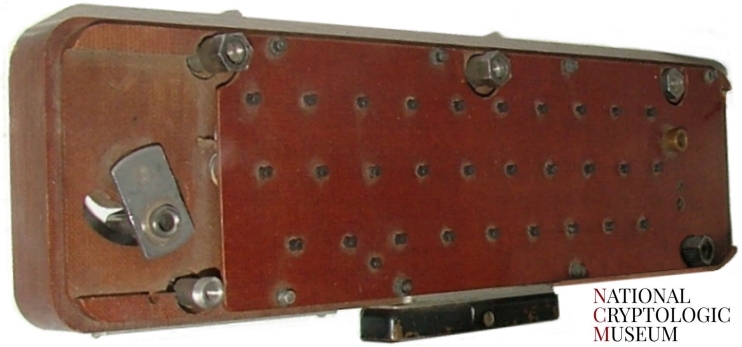

The Cipher Unit

* The detachable KLK-7 Cipher Unit, also

called rotor cage or basket, holds the eight rotors that are selected from the key list.

The KL-7 uses a complex re-entry system that can

cause multiple enciphering of a single character.

Note that the re-entry drawing is a simplified example with three 6-pin rotors and 2 re-entry connections. In reality, the cipher unit holds eight 36-pin rotors and has 10 re-entry wires. Moreover, the 36 wires from the end plates are connected in a scrambled order to the flat contacts at the bottom of the Cipher Unit. (see table base and end plate connections below). When the signals leaves the exit rotor, there are two possible situations. The signal is either is passed directly to the pulse generator through one of the 26 wires, or leaves the exit rotor through one of the 10 re-entry contacts. In the latter case, the signal is rerouted back to one of the entry rotor's 10 re-entry contacts to perform an additional pass through the rotors, which can repeat multiple times before arriving at the Pulse Generator. Depending on the internal wiring and current position of the rotors, the signal performs 1 up to 11 passes through the eight rotors before leaving the exit rotor towards the pulse generator. Each stepping of the rotors results in a new and most complex signal path that changes in both number of passes and its route through the eight rotors. The cipher unit has on the left a fixed end plate with axle to slide the rotors onto, 36 spring-loaded contacts in a circular fashion on the inside, and at the bottom 26 flat contacts and 10 flat re-entry contacts. The removable end plate on the right has 36 flat contacts in a circular fashion on the inside, and at the bottom 26 flat contacts and 10 flat re-entry contacts. The 26 flat contacts on both endplates make contact with spring loaded pins on the Base, which are connect to the 26 letters from the sliding contact board. The 10 flat re-entry contacts make contact with spring loaded contacts on the rotor stepping unit that connects the wires of both sides straightforward between left and right, i.e. 0-0, 1-1, 2-2 and so on, to act as re-entry loops. |

|

|

Once all rotors are inserted, the cipher unit is placed in the rotor stepping unit and fixed with two locking levers at the front left and right of the stepping unit. The table below shows the wiring order between base and cipher unit end plate pins. The pins are numbered clockwise (seen from the left) and pin 01 is aligned with the white index stripe on the cipher unit windows. Both cipher unit end plates are wired identically. The letter “Q” from the sliding contact board wired to end plate pin 01, letter “P” to pin 02 and so on. The digits 0 through 9 represent the re-entry wires. |

|

| Base connections | Q | P | 0 | N | F | C | 3 | Y | O | M | 9 | G | R | 8 | U | I | 7 | B | H | 2 | V | T | W | 6 | X | S | 4 | J | L | Z | 5 | D | K | E | A | 1 |

| End Plate Pins | 01 | 02 | 03 | 04 | 05 | 06 | 07 | 08 | 09 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 | 27 | 28 | 29 | 30 | 31 | 32 | 33 | 34 | 35 | 36 |

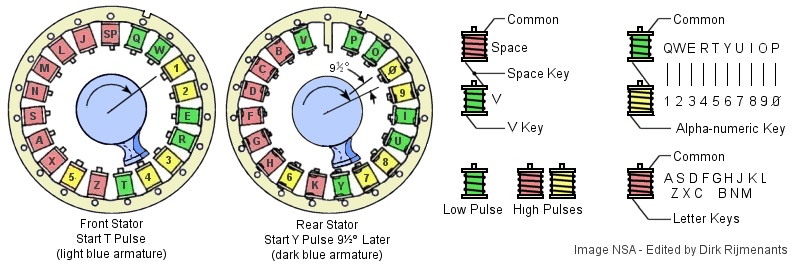

The Pulse Generator

When a key is depressed, the pulse generator converts the signal that passed through the rotors and the keyboard into accurate timing signals for the electronics to control the printer and to activate the clutch of the timing unit, which also provides mechanical power to the rotor stepping unit.

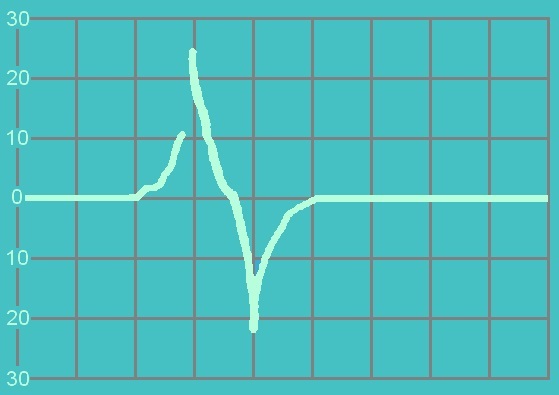

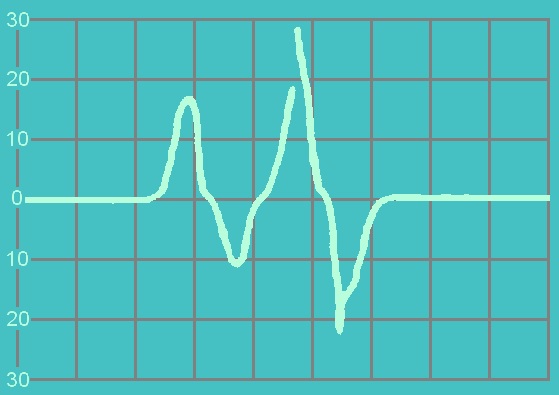

The print hammer must activate at the exact moment a given letter on the rotating printer drum passes the hammer. To achieve this, the pulse generator provides exact timing. It consists of a magnetic armature, rotating clockwise at 2200 rpm, and two stators with pulse coils. The print wheel with all letters and figures rotates on the same axle. When the electronics receive a pulse from a coil it will activate the print hammer at the appropriate moment. There are 37 coils for 26 letters, 10 figures and the space.

The

front stator has 19 coils. The rear stator has 18

coils and is positioned exactly behind the front

stator. The rotor armature (blue at above image)

has two separate magnetic poles, one for each

stator. The rear pole lags 9.47 degrees behind

the front pole. This ensures that only one coil

at a time is induced, the front coil first and

rear coil following.

The KL-7 combines the 10 figures with 10 letters in the top row alpha-numeric keys. The electronics must therefore detect the difference between printing a letter or its corresponding figure. To do so, the alpha-numeric keys have two coils in series, a negative 5 volts low pulse coil (green) for letters and a negative 10 volts high pulse coil for figures (yellow). One special coil combination is the letter V low pulse coil in series with the SPACE high pulse coil and a junction between the coils. These are part of the piggyback system. All other letters have a single negative 10 volts high pulse coil (red). The difference between the low and high coils is the size of their core and winding. Note that the red and yellow high pulse coils are identical and only differ in color to distinguish letter and figure coils in the drawing. Depressing a key grounds its corresponding coil, generating a transient pulse that activates the Gate tube. The Gate tube determines the time frame in which the Print tube is allowed to process a character pulse. This ensures that only the current pulse activates the Print tube, and any following stray pulses are ignored. For more details on the generation of pulses, see signal timing. The common - negative - side of the pulse coils is connected to the step-up transformer. When the pulse generator armature passes the grounded coil, it will induce a pulse. The 1:3 step-up transformer inverts the negative pulse phase and raises the -5 to +15 volts or -10 to +30 volts to prepare the pulse for the Sharpener tube control grid (see images). The Sharpener tube passes the cleaned-up pulse to the Print tube. To conduct, the Sharpener tube control grid potential must be higher than the tube's cathode potential. If the control grid potential is lower than the cathode, this represents a negative bias, and the Sharpener cannot conduct. To make the Sharpener conduct, the incoming positive pulse on its grid must overcome or "pull up" the negative bias enough. This negative bias acts as a threshold (i.e. hurdle) enabling the Sharpener tube to distinguish low and high pulses. More on how the electron tubes work is found in the electronics section. The Shift tube holds the current shift mode. In LET mode, the Shift tube puts 8 volts on the Sharpener cathode. Without pulse, the transformer grounds the Sharpener grid to 0 volts, causing a minus 8 bias (0 - 8 = -8). In FIG mode, the Shift tube increases the Sharpener cathode potential to 22 volts, causing a minus 22 bias (0 - 22 = -22). In LET mode, the default minus 8 volts bias is a low threshold and the Sharpener tube will accept both high pulse letters ( -8 + 30 = +22) and low pulse letters from the alpha-numeric double-pulse (-8 + 15 = + 7) but its associated high pulse figure, although high enough ( -8 + 30 = +22), does not trigger the Sharpener tube because the tube's 11 ms recovery time is longer than the 2.88 ms between the two pulses (only one coil distance, e.g. Q and 1). In FIG mode, the Shift tube increases the bias to approximately minus 22 volts, resulting in a higher threshold. The Sharpener tube then ignores the alpha-numeric low pulse letters as they don't pass the threshold (-22 + 15 = -7) and will only react on alpha-numeric high pulse figures (-22 + 30 = +8). The following situations will occur when depressing any key:

The Gate tube prevents repeating or stray pulses, but not using this function also enables the repeat key. The RPT repeat key forces the Gate tube to keep the Print tube ready. When pressing the RPT simultaneous with another key, that character is printed continuously. Depressing a key will always activate the printer and the timing unit clutch. Note that the space key only activates the clutch and advances the paper one step without printing, and the space and piggyback letters are swapped and print other characters, depending on the state of the sliding contact board (see also letters and figures). |

|

The Printer

The fixed pulse coils

for 26 letters, 10 figures, a space and blank are

placed clockwise on the pulse generator.

with the double stator alternating between front

coil first and rear coil behind it, in the order

as shown below, starting with the Q front coil at

the top (space and blank represented by a dash).

QPWO1029EIRU3847TYZK56XHAGSFNDMCLBJV-- The KL-7 has a continuously clockwise rotating print drum at 2200 rpm, fixed on the same axle as the pulse generator. The print drum has the same character sequence on its circumference, but counterclockwise, which is the exact reverse order to the pulse coils. This seems counterintuitive. However, seen from the front, the clockwise rotating print drum passes the print hammer at the bottom from right to left. The characters Q, P, W, etc. must therefore pass one by one at the bottom, from right to left. Thus, the characters Q, P, W, etc. are placed at the bottom of the print drum from left to right, i.e. counterclockwise. The moment the magnetic armature of the pulse generator passes a grounded coil, the transformer, Sharpener and Print tube pass this signal to the print hammer and the timing unit clutch. The print hammer pushes the paper and inked ribbon upwards against the print drum, at the exact moment that the required character passes the print hammer. The two ink ribbon spools are behind the removable black cap. A pin, controlled by the sliding contact board, mechanically switches between continuously printing (plaintext) and five-letter groups with a space between each group (ciphertext). The paper roll is stored in the black circular casing between the motor block and the cipher unit. |

|

The Timing Unit

The timing unit

controls four cam switches that generate timing

signals for the electronics,

provides mechanical power to advance the paper

strip, the ink ribbon, and the pawl system of the

rotor

stepping unit to

advance the rotors. The timing unit clutch is

engaged by the trip magnet.

When the Print tube energizes the trip magnet, its rod* (yellow) is briefly removed from under the clutch pawl stop bulge* (light green). The spring-loaded clutch pawl can now move inward and its single tooth (light green) grabs into the clutch drive gear (dark blue), connecting the running DC motor through the gears to the camshaft (in reality, the trip magnets are located directly underneath the clutch). Once a revolution is completed, the clutch pawl arrives back at its original position above the meanwhile returned rod, which now pushes the clutch pawl back upwards, causing the clutch pawl single tooth to disengage from the gear. As the gears have an 11:1 motor/timing ratio, the timing unit performs one single revolution at 600 rpm in 0.1 second. During this cycle, the four cam switches send their timing signals to the electronics, and the paper strip and ink ribbon move one step further. The rotation of the timing unit and cam switches is in sync with all other mechanical processes of the KL-7. Also during this cycle, only those rotors that have been released by their associated stepping magnet are advanced one step. Thanks to the timing signals, the electronics know when the mechanical cycle has been completed. The cam switches on the timing shaft control the following functions:

More about the cam switches in the electronics section. |

|

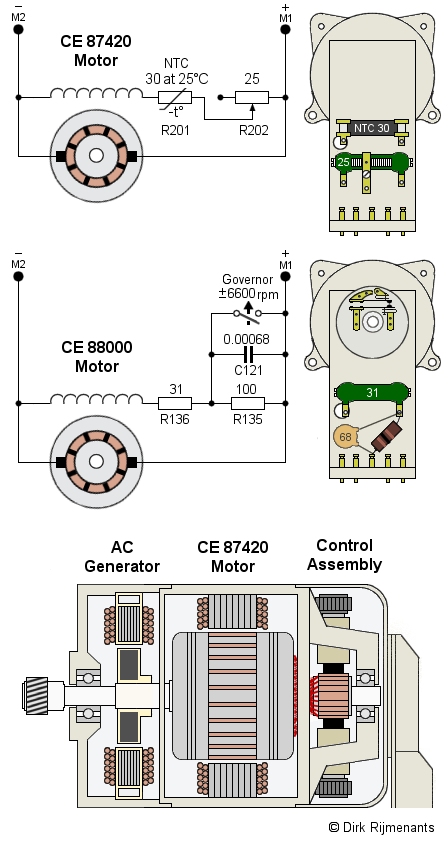

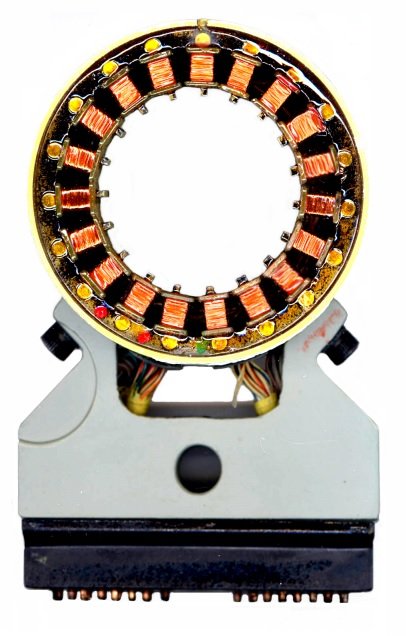

The Motor-Generator

The motor-generator, providing both mechanical

power and AC voltage, is a combination of a 24 volts DC

motor and a 400 cycle AC power generator delivering 5

Watts and 150 volts rms at 6600 rpm, together in one

single housing.

The motor-generator, providing both mechanical

power and AC voltage, is a combination of a 24 volts DC

motor and a 400 cycle AC power generator delivering 5

Watts and 150 volts rms at 6600 rpm, together in one

single housing.

The motor exists in two versions. The CE 87420 was replaced from serial number 13149 by the improved CE 88000. The difference is how the current through the field winding is controlled.

The components to control the motor speed are not included in the general electronics because the controller assembly is housed inside a cover at the back of the motor-generator (see image, resistors in ohm, capacitor in microfarad).

The CE 87420 is a shunt wound DC motor where the armature and shunt field are connected parallel, which typically produces a modest starting torque but has good speed stability under varying load because its speed is self-regulated.

When the speed of the rotating armature drops, the counter-electromotive force (CEMF) also drops and more current can flow through the armature, increasing torque and motor speed. When speed rises, the CEMF also rises and less current can flow through the armature, decreasing motor speed. This feedback creates speed stability, regardless the load.

The motor speed is adjustable by changing the current through the field winding, which also changes the amount of CEMF and thus motor speed. This is done by the adjustable resistor R202 to compensate manufacturing variations of the field winding and the NTC resistor R201 (Negative Temperature Coefficient).

The newer CE 88000 is also a shunt wound DC motor with self-regulating speed but has an additional centrifugal “governor” switch to maintain a constant speed while operating at voltages ranging from 21 to 31 volts DC. The Governor speed adjustment is set at 6600 +/- 100 rpm.

The governor switch is open when motor speed is low. Resistors R135 and R136 are then in series, causing a lower current through the field winding. The resulting lower CEMF speeds up the motor. When the motor reaches its optimal speed, the governor closes and short-circuits R135. The resulting higher current through the field winding causes a higher CEMF that slows down the motor.

The motor speed is adjustable with the upper screw on the governor. The lower screw adjusts the air gap between the contacts. Capacitor C121 suppresses sparks on the governor and R136 limits current surge when the governor closes.

The AC

generator is mounted in front of the motor on the same

shaft. The generator rotor is a permanent magnet that is

also fixed to the shaft. The rotating magnet induces the

high voltage in the stationary field coils.

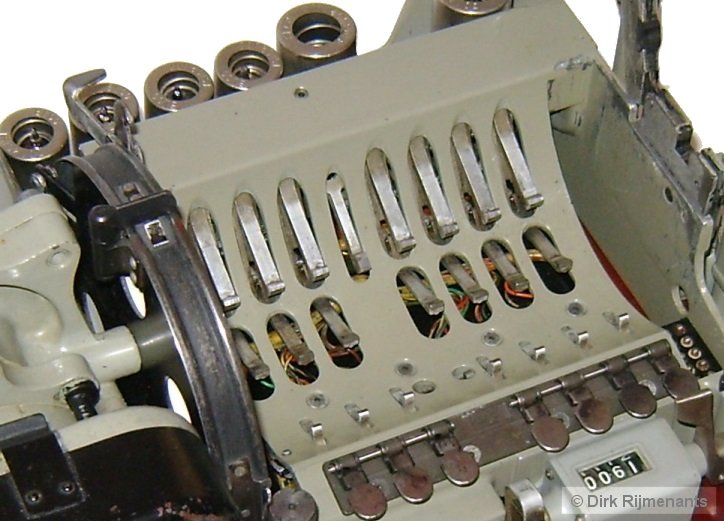

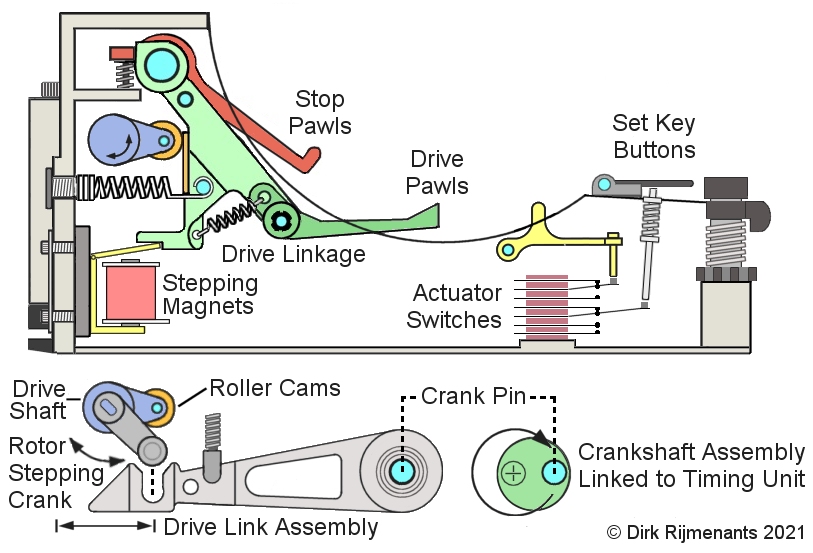

The Rotor Stepping Unit

The KLA-7 rotor

stepping unit supports the cipher unit (rotor cage) and controls the stepping

of the rotors. At the rear of the cradle, there

are eight large stop pawls that prevent any

non-moving rotor from moving along with

neighboring moving rotors. The fourth stop pawl

normally isn't used but keeps that fourth rotor

in place when testing the rotors on a special

axle without the rotor cage shell.

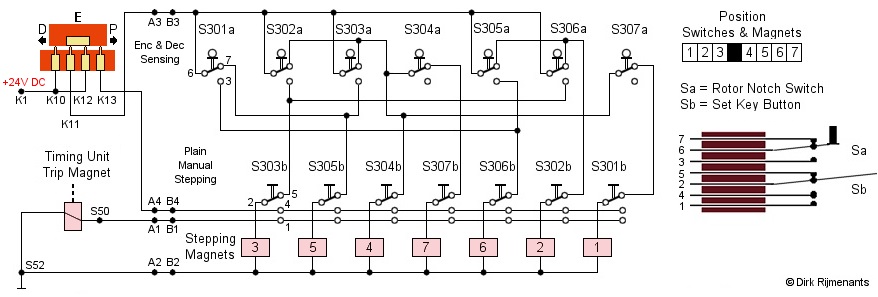

In the middle of the cradle are seven drive pawls to advance the rotors by grasping the notches in the rotor alphabet ring. These pawls are mechanically powered by the timing unit, under control of seven stepping magnets from the stepping logic. In front of the drive pawls are seven tiny cams from actuator switches that read the notch rings on the rotors. These pile-up switches control the stepping logic for the stepping magnets. Just before the cradle are seven Set Key buttons to manually advance each individual rotor. When a key is depressed, the pulse generator passes the signal to the Print tube which in turn will activate the timing unit that executes a single cycle. The stepping of the rotors is mechanically driven by the timing unit side shaft that rotates the crankshaft assembly for the rotor stepping unit. The crankshaft assembly has an eccentric crank pin, connect to the drive link assembly to convert the rotation into a back-and-forth movement that is passed to the drive shaft by the rotor stepping crank. There are 7 ball-bearing roller cams fixed to the drive shaft, or one for each moving rotor (forth rotor doesn’t move). The roller cams hold the drive linkage forward. When the timing unit cycles, the drive shaft rotates 75 degrees in clockwise direction and the 7 rollers move downwards, away from the 7 drive linkages. Each drive linkage has a spring that pulls the linkage backwards. However, when the stepping magnet of an associated drive linkage is not energized, the magnet prevents that drive linkage from moving backwards. During a cycle, some of the stepping magnets are energized by the stepping logic, under control of the 7 actuator switches. When a stepping magnet is energized and the drive shaft turns the roller cams away from drive linkages, the associated drive linkage moves backwards, causing its drive pawl to move backwards. At the same time, the drive linkage also releases the associated stop pawl, which is then pushed downwards by the stop pawl spring to enable its rotor to move. Simultaneously, the drive pawl sloped end slides backwards out of the alphabet ring notch. When the drive pawl arrives at the next notch, the small spring on the drive linkage will force the drive pawl upward into the next alphabet ring notch. |

|

When the drive shaft has reached its maximum swing angle backwards, the roller cams return forward and push any released drive linkages back to the forward position. The flat end of the drive pawl pushes its rotor one step further. The drive linkage also forces the stop pawl upward into a free alphabet ring notch. During any stepping cycle, these stop pawls prevent non-moving rotors from moving along by the friction of moving neighboring rotors.

On the right of the drawing are the 7 actuator switches that sense the white notch rings on the rotors. In the Plain mode, the operator can use the 7 Set Key buttons to manually step the individual rotors and set them in the proper position (see procedures enciphering and deciphering). During enciphering and deciphering, each key stroke causes some of the rotors to step in a highly irregular fashion under control of the 7 actuator switches.

In the circuit diagram below, all actuator switches are shown inactive. Each switch is a pile-up of the two sections, Sa and Sb. Note that the order of the upper Sa section is as actually positioned in the rotor stepping unit. The order of the lower Sb section and the stepping electromagnets is mixed to make the circuit diagram more readable, and these are actually placed from left to right according to their number. There are only 7 switches and stepping magnets because the stationary fourth rotor is skipped. The pins on all switches are numbered the same as on switch S301a and b.

The stepping circuit is

powered by the same 24 volts DC that powers the DC motor and the tube filaments.

The switch (orange) is part of the sliding contact

board and determines

which part of the circuit is powered, depending

on the cipher mode.

In Encipher (E as shown in drawing) and Decipher (D) mode, only the upper Sa section of the switch pile-up, used for sensing the notch rings, is powered (route K1 - K12 or K10 - K11 - A3 - B3). Magnets 2 through 6 are each controlled by two switches in OR logic. These magnets are activated when at least one of the two switches has the appropriate state. Magnets 1 and 7 are controlled by three switches and are activated when one switch is inactive AND at least one of two other switches is inactive. At least two magnets are always active at any given moment. In Plain mode, only the lower Sb section is powered (route K1 - K12 - K13 - A4 - B4). Depressing a Set Key button first energizes its stepping magnet through contacts 4 and 2 to release the corresponding drive linkage. A fraction later, contact 4 is pushed further down against contact 1 and energizes the trip magnet, causing the timing unit to perform a cycle and provide mechanical power to step the corresponding rotor. If the Set Key button is still held down after completing the cycle, the rotor will continue to step until the button is released. The stepping logic is wired in such a way that a situation where none of the rotors move is avoided as this would cause the rotors to halt permanently. The logic table on the right shows the required notch combinations to move a rotor. The stepping of a single rotor is controlled by two or three separate notch rings. Two notch rings can produce a maximum period (unique movement sequence) of 1,296 and three rings a maximum period of 46,656. This is for one single rotor. The combination of seven notch rings therefore provides a most complex stepping sequence. |

|

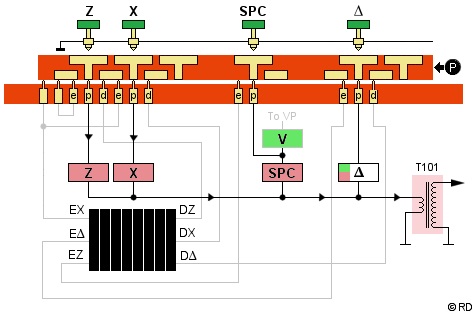

Letters and Figures

To enable enciphering 37 different characters into letter-only code groups, the KL-7 uses a system, similar to the teletype code. Two signals, LET and FIG, switch the machine between letters and figures. Both character sets use the same signals, and they are distinguished only by the FIG or LET mode on that particular moment. To show the current state, a neon bulb lights up when the KL-7 is in FIG mode. The characters “QWERTYUIOP” are processed as “1234567890” in FIG mode.

This still gives 26 alpha (-numeric) keys, the additional SPACE, LET and FIG. The KL-7 must encipher these three additional characters into a letter. Therefore, the KL-7 design permits the special functions to piggyback on some of the existing alphabet letters. The letters “J”, “V”, “X”, “Y” and “Z” were selected because they are some of the less frequently used letters.

To accomplish the piggyback of the SPACE key on letter Z, the sliding contact board reroutes the X, Z and SPACE signals. The following drawings explain the rerouting of those letters in the different modes.

Notes:

1. Below, any unspecified letter, key

or pulse coil (A through Z) is denoted by Δ (delta). Underneath each key

are three contacts, named e-p-d (encipher - plain -

decipher. Thus, the contacts underneath the A key are

named Ae, Ap and Ad. The left side contacts of the cipher unit that holds the rotors are named EA through EZ

(Encipher this letter) and the right-side contacts are

named DA through DZ (Decipher this letter). See sliding contact board for routing through rotors.

2. The actual direction of the current is opposite to the

direction of arrows in the diagrams, because the pulse

coils produce a negative pulse. The arrows are used

solely to demonstrate the path from key to transformer.

See pulse

timing signals for more

details.

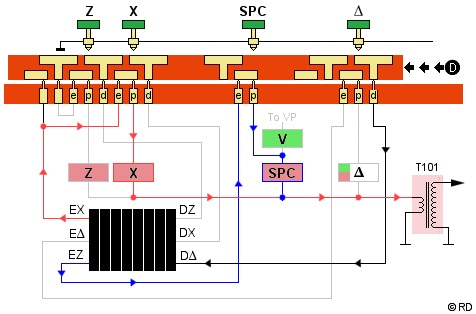

Plain Mode

Plain Mode

In plain mode, the p-contact of each key is connected to its corresponding pulse coil (black route). Zp to the Z coil and Xp to the X coil. Both are high pulse coils (red). Depressing the letter Z or X will close the circuit of its corresponding coil. When the magnetic armature of the pulse generator passes that coil, the induced signal is stepped up by transformer T101, passed to the sharpener and print tube, and printed.

The SPACE key is connected to a junction on the V-SPACE coils pair. This special feature is also used in the separate FIG circuit. By using the junction, depressing the SPACE key will only close the SPACE coil circuit.

All other keys are also connected via their p-contact to the corresponding pulse coil. These coils can be high pulse letter coils (red) or low pulse alpha-numeric coils (green). The low pulse V coil from the V-SPACE pair is connected to the V key's Vp contact.

In plain mode, the signals do not pass

through the rotors in the cipher unit.

Encipher Mode

Encipher Mode

In encipher mode, the e-contact of each key is normally connected to the corresponding E-contact on the cipher unit left side. This however is not the case with the piggyback Z key.

The Z and X key e-contacts (red route) are now both switched to the EX-contact (Encipher X) on the cipher unit left side. This doesn't affect the X, but the letter Z also becomes X, because the SPACE needs the Z to piggyback.

Therefore, the SPACE key's e-contact (blue route) is connected to the cipher unit left side EZ-contact and actually enciphers the letter Z that will represent the SPACE.

The enciphered version of all letters exits the cipher unit right side at one of the D-contacts. This can be any of the 26 letters DA through DZ, even the depressed key itself, depending on the rotor positions and wiring.

The signal then travels to the key that

corresponds with the cipher unit's D-contact, enters that

key's d-contact, passes its small connecting bar and its

p-contact to the pulse coil, and prints the enciphered

letter.

Decipher Mode

Decipher Mode

In decipher mode, the d-contact of each key is connected to the corresponding D-contact on the cipher unit right side (black route). The only exception is the SPACE key, which is not used, as only letters are to be deciphered.

The deciphered version of all letters exits the cipher unit left side at one of the E-contacts. This can be any of the 26 contacts EA through AZ, even the depressed key itself, depending on the rotor positions and wiring.

The signal then travels from that E-contact to the key that corresponds with the deciphered letter, enters that key's e-contact, passes its connecting bar and p-contact to the pulse coil, and prints the deciphered letter.

When a depressed key represents the enciphered X, the signal exits the cipher unit as deciphered letter X on the left side EX-contact. The signal (red route) then travels to the Xe contact and via a connecting bar to the X coil, to print the X. Thus, both originally plain X, and the Z (changed into X) are deciphered and printed as X.

When the depressed key represents the enciphered Z, the signal exits the cipher unit left side as deciphered Z at the EZ-contact. Since the deciphered Z actually represents a SPACE, the signal (blue route) does not travel to the Ze contact, but via the SPACE Key's e-contact and connecting bar to the SPACE coil to print a space.

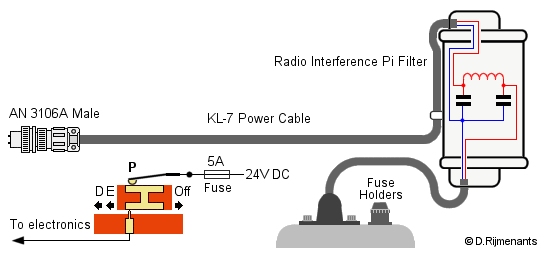

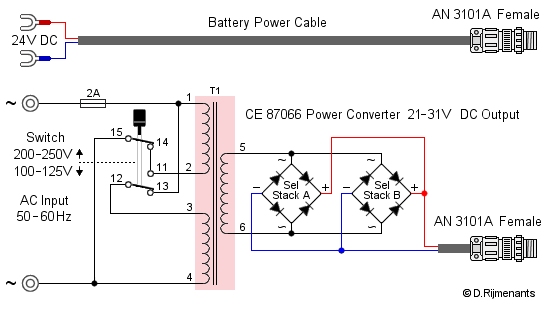

The Electronics

The KL-7 can be powered in two ways. The Power Cable, connected to a 24 volts DC source (e.g. vehicle battery) or the AC Power Converter that converts 110V or 220V AC into 21 to 31 volts DC (24 volts is ideal). Both power cable and converter have an Amphenol AN 3101A Mil Spec connector (2 pins female) with AN 3057-4 cable clamp that mates with the KL-7's power cable with male connector. The Power Converter has two fuse holders at the back, with one fuse to protect the circuit and one spare fuse.

|

CE 87066 Power

Converter |

|

The AC Power Converter

has a switch to select the AC input voltage. For

100-125 volts, the two primary windings are

switched parallel (routes 1w2-11-14-15 and

1-13-12-3w4). For 200-250 volts, the primary

windings are switched in series (route

1w2-11-12-3w4). Since the primary windings

switched in series have twice as many turns as in

parallel, the output voltage is inversely halved

and thus remains 24 volts.

The secondary winding is connected to two selenium full-wave bridge rectifier stacks connected parallel. The first version of the power converter produced 2.4 Amps output current. The newer version with 4.5 Amps (as of sn15413) is more efficient for the KL-7 with second generation motor-generator with governor switch. The higher current is also better when the selenium rectifiers are aging. The AC Power Converter measures 10.6 x 4.7 x 4 inches (27 x 12 x 10 cm). |

|

The

KL-7 itself has a power cable with AN 3106A

connector (2 pins male), connected to the Radio

Interference Filter which is mounted in

the right-side rack (see photo mode

selector). From the

filter, a short cable enters the KL-7 at the

right-side top of the keyboard. Via two fuses and

two slide contacts, the 24 volts arrive at the

double T contacts (see also circuit diagram

below). The rack also carries a dummy female

connector to secure the power cable during

transport.

The filter suppresses voltage variations on the power cable as these can cause interference on the mains grid or even piggy-back on the modulated signals of nearby radio equipment, leaking signals that could be exploited by the adversary, even at great distance. The Pi-type filter attenuates these signals over a wide band of frequencies. The filter assembly was sealed, and maintenance or repair was not allowed. If the filter malfunctioned, the complete filter assembly had to be replaced. More about the security risks of stray signals is found on our TEMPEST page. |

|

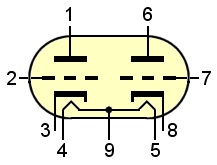

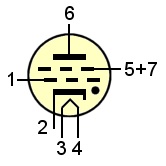

To follow the KL-7 circuit diagram below, we need to know the type of electron tubes (valves) and how they function. These are crucial to process the printer timing signals. The KL-7 has one 12AX7 and three 2D21 tubes. These were produced by many manufacturers like RCA, General Electric, Brimar or Mullard. For military supply contracts, the tubes were designated JAN 12AX7 and JAN 2D21 in the Joint Army-Navy Nomenclature System. This JAN specification, adopted by the Joint Communications Board in 1943, is a predecessor of the current Joint Electronics Type Designation System or JETDS (MIL-STD-196).

* The 12AX7 Twin Triode

vacuum electron tube has two separate triodes

(three electrodes each) making it suitable for

use as multivibrator. For each triode, the

current that flows from the plate (pin 1 or 6) to

the cathode (3 or 8) is controlled by a small

voltage on the control grid (2 or 7). The more

positive the control grid bias is, the more

current flows from the plate to the cathode. A

negative control grid bias stops the flow of

current. The 12AX7 has two heater filaments in

series with center-tap (4 - 9 - 5), making it

possible to operate the two filaments parallel at

6.3 volts, as being used in the KL-7, or in

series at 12.6 volts (data sheet * The 12AX7 Twin Triode

vacuum electron tube has two separate triodes

(three electrodes each) making it suitable for

use as multivibrator. For each triode, the

current that flows from the plate (pin 1 or 6) to

the cathode (3 or 8) is controlled by a small

voltage on the control grid (2 or 7). The more

positive the control grid bias is, the more

current flows from the plate to the cathode. A

negative control grid bias stops the flow of

current. The 12AX7 has two heater filaments in

series with center-tap (4 - 9 - 5), making it

possible to operate the two filaments parallel at

6.3 volts, as being used in the KL-7, or in

series at 12.6 volts (data sheetIn the KL-7, the 12AX7 is used as single-shot multivibrator Gate tube, to determine the time frame within the Print tube is allowed to fire. Although the physics are quite different, you could compare the triode with a modern NPN transistor, where current from collector to emitter is controlled by the base.

In the KL-7, the 2D21

Sharpener, Shift and Print tubes are used to

switch the character pulses and their threshold,

and the Print and Trip magnets. A thyratron acts

as a fast switch, similar to a modern thyristor,

where the current is switched by its gate

voltage. Note that a tetrode electron tube,

without any gas, will not act as a switch,

but works similar to a triode electron tube with

an additional grid. See also how electron tubes

work in Mr Carlson's Lab

YouTube video Below is the full circuit diagram. All electronics are located underneath the Contact Panel Assembly, except for the electron tubes, located behind the Rotor Stepping Unit. The components in the circuit diagram are labeled in the same way as the original maintenance manual and circuit diagram. Since the original diagram is pretty hard to read, the different sections of the electronics are presented here well separated. The orange dots represent parts of the sliding contact board. At the top left of the circuit diagram is the power supply for all electronics. The 24 volts DC arrives at two double T contacts on the sliding contact board and powers the Motor-Generator that provides mechanical power and high-voltage. The 24 volts that power the DC motor is also used for the filaments of the four electron tubes and the stepping magnets in the Rotor Stepping Unitt. The full-wave bridge rectifier, followed by two diodes, provides +220 volts at terminal W4. The bridge rectifier + is also directly connected through terminal W8 to resistors R109 and R110 to provide +200 volts at terminal W2 for some parts of the circuit. A half wave rectifier provides the negative 72 volts. |

RCA 12AX7 Twin Triode and 2D21 Thyratron  Original General Electric JAN 12AX7 WA Joint Army-Navy electronics standard © Photo TubeDepot |

The pulse

generator in the center left

converts a key stroke into one or two negative pulses

when that pulse coil is grounded and induced by a

rotating magnetic armature. 15 letter keys have a single

high pulse coil. 10 alpha-numeric keys have a low pulse

and high pulse coil in series. For the piggyback system, the V key has a low pulse coil in series with

the SPACE key high pulse coil and includes a junction.

The pulse

generator in the center left

converts a key stroke into one or two negative pulses

when that pulse coil is grounded and induced by a

rotating magnetic armature. 15 letter keys have a single

high pulse coil. 10 alpha-numeric keys have a low pulse

and high pulse coil in series. For the piggyback system, the V key has a low pulse coil in series with

the SPACE key high pulse coil and includes a junction.

When a key is depressed, a negative pulse triggers the V104 Gate tube, which acts as single-shot multivibrator that controls the Print tube shield grid bias, to limit when the Print tube is allowed to activate the printer. Next, when the armature passes the coil of the depressed key, a negative pulse is sent to the T101 step-up transformer in the center, which inverts the pulse (see also signal timing).

In the center of the diagram is the V102 Sharpener tube that receives the pulses from the step-up transformer. The Sharpener serves as threshold to distinguish low and high pulses. When V102 is not ionized, its cathode has the same potential as terminal W5, determined by the V103 Shift tube via the R119 - R122 - R123 resistor network.

In LET mode, a low pulse is sufficient to overcome the minus 8 voltsbias on the Sharpener tube control grid. In FIG mode, the increased voltage drop on terminal W5 makes the Sharpener control grid bias more negative, requiring a high pulse to fire the sharpener.

The V101 Print tube only fires when the triggered Gate tube makes the Print tube shield grid bias positive, and the Sharpener tube pulse simultaneously makes the Print tube control grid bias positive.

When the Print tube has activated the timing unit, the Repeat Cam switch disconnects the positive voltage from the Gate tube's A plate (anode), turning the Print tube shield grid bias negative. This prevents the Print tube from firing successive pulses or stray pulses from keyboard, or from moving rotor pins.

Once the cycle and rotor stepping are completed, the Repeat Cam switch closes again, and both Gate and Print tube are ready for the next cycle.

When the RPT key (repeat) is depressed, the negative bias on terminal X1 and on the Print tube shield grid is removed and the tube is ready to fire at any pulse it receives from the Sharpener tube. Depressing the RPT key together with a letter key will therefore continuously print the depressed plain or enciphered letter.

When the Print tube fires, the print and trip magnet are activated. Both magnets are energized in a quite special way. The Print capacitors C101 & C102 and Trip capacitors C106 & C107 are constantly charged though R109 and R110 to +200 volts. Since charged capacitors don't draw current, no current flows through the Trip Magnet circuit. When the Print tube fires, this shorts the circuit and discharges the capacitors though the tube-print-trip circuit, in series with the capacitors. Their discharge current energized the Trip Magnet.

This activates the timing unit to perform one cycle, and switches on the camshaft provide four timing signals. During this cycle, the Charge Cam switch shorts the 10K resistor R110, leaving only the 1K resistor R109 between the 220 volts at W8 and the capacitors at W2, ensuring a fast recharge of the capacitors to be ready for the next machine cycle. The Charge Cam switch also disables the Print tube until the cycle is finished, preventing the Print tube from firing multiple times during a cycle.

At the bottom of the circuit diagram is the Shift tube section that memorizes the current shift mode, shows the current mode with a neon lamp, and controls the threshold of the Sharpener to know what signals to accept in LET or FIG mode.

The switches with an orange dot in the above circuit diagram represent parts of the sliding contact board and shows how they influence the stepping of the rotors, the shift mode circuit and some of the keys. How those switches work is shown below.

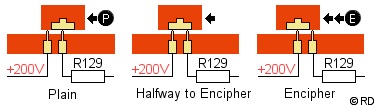

Auto Space Switch. When

the mode

selector switches

between Plain and Encipher, the Auto Space Switch

quickly discharges the Print and Trip capacitors

through the R129 resistor, causing the Print and

Trip magnets to initiate a single cycle of the timing unit and stepping of the rotors. This

scrambles the positions of the rotors, depending

on the notch rings, which is used in the enciphering

procedure. On the

drawing you see the actual switch on the sliding

contact board. In Plain, the resistor is only

connected to the bridge and the switch is not

activated. When the bridge is halfway towards

Encipher position, the +200V is connected briefly

to the resistor to discharge the capacitors.

Auto Space Switch. When

the mode

selector switches

between Plain and Encipher, the Auto Space Switch

quickly discharges the Print and Trip capacitors

through the R129 resistor, causing the Print and

Trip magnets to initiate a single cycle of the timing unit and stepping of the rotors. This

scrambles the positions of the rotors, depending

on the notch rings, which is used in the enciphering

procedure. On the

drawing you see the actual switch on the sliding

contact board. In Plain, the resistor is only

connected to the bridge and the switch is not

activated. When the bridge is halfway towards

Encipher position, the +200V is connected briefly

to the resistor to discharge the capacitors.

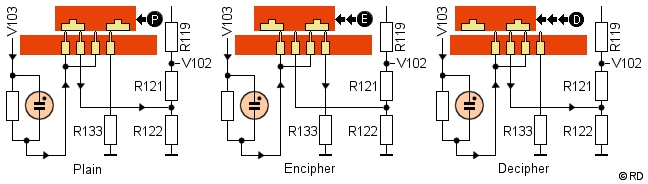

Shift Mode Switch. This

switch allows in Plain and Decipher mode to pass

the current shift mode through the R119 - R121 -

R122 resistor network to the V102 Sharpener tube.

However, in Encipher mode the KL-7 should only

print ciphertext letters. The Shift Mode switch

therefore disconnects in Encipher mode the

resistor network from the V103 Shift tube to keep

the Sharpener in LET mode. The neon lamp then

only serves as an indication of the shift mode.

On the drawing you can follow the path from the

shift mode through the resistor and neon lamp to

the resistor network (plain and decipher) or

disconnected and passed to R133 (encipher).

Shift Mode Switch. This

switch allows in Plain and Decipher mode to pass

the current shift mode through the R119 - R121 -

R122 resistor network to the V102 Sharpener tube.

However, in Encipher mode the KL-7 should only

print ciphertext letters. The Shift Mode switch

therefore disconnects in Encipher mode the

resistor network from the V103 Shift tube to keep

the Sharpener in LET mode. The neon lamp then

only serves as an indication of the shift mode.

On the drawing you can follow the path from the

shift mode through the resistor and neon lamp to

the resistor network (plain and decipher) or

disconnected and passed to R133 (encipher).

- Repeat Key. The pins of this key are connected through the sliding contact board to the shield grid of the V101 Print tube in both Plain, Encipher and Decipher mode. Depressing the RPT key together with a letter key therefore continuously print that letter in all modes.

The letters cam switch and figures cam switch from the timing unit control how the piggyback letters for LET and FIG keys are processed. Since we have the Plain, Encipher and Decipher mode and two shift modes, there are six different ways these keys are processed. To accomplish this, the sliding contact board reroutes the FIG and LET keys, and the figures and letters cam switches.

Note: Below, the unspecified key, letter or pulse coil (A through Z) is denoted by Δ (delta). Also, the actual circuit uses a few more switches on the sliding contact board to avoid conflict with other key circuits in the different modes, but the route of the signals is as shown below.

The FIG key operation:

Plain mode. The FIG key

is connected directly to FIG contact (3) of the

Shift tube circuit. Depressing the key instantly

activates the FIG mode and the neon lamp lights

up. No actions are required to step the rotors as

there is no enciphering. What you type is what

you print.

Plain mode. The FIG key

is connected directly to FIG contact (3) of the

Shift tube circuit. Depressing the key instantly

activates the FIG mode and the neon lamp lights

up. No actions are required to step the rotors as

there is no enciphering. What you type is what

you print.

- Encipher mode.

The FIG key enters the cipher unit as

piggyback letter J at the EJ contact. Its

enciphered version exits the cipher unit at the DΔ contact and is

routed through the Figures Cam Switch to the Δ pulse coil to print

that letter. Since LET mode has a low threshold,

all low and high pulse letters are printed. The

timing shaft rotates, and at 10 degrees the

Figures Cam Switch changes connection to the FIG

contact (3) of the Shift tube circuit. The neon

lamp lights up, but only acts as an indication

for the operator. The machine itself stays in LET

mode to print ciphertext letters (see Shift Mode

Switch).

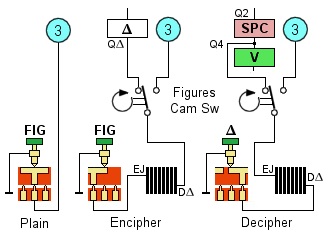

- Decipher mode. The letter Δ, representing the enciphered letter J, is depressed and enters the cipher unit at the DΔ contact. The deciphered version exits the cipher unit at the EJ contact as piggyback letter J and is routed through the Figures Cam Switch to the SPACE junction (part of the V-SPACE coils pair). Although in series with the V coil, the SPACE is printed because its coil is grounded separately from the V coil. The timing shaft rotates, and at 10 degrees the Figures Cam Switch changes connection to the FIG contact (3) of the Shift tube circuit. The machine is set to FIG mode, and the neon lamp lights up.

The LET key operation:

Plain mode. The LET key

is connected directly to LET contact (4) of the

Shift tube circuit. Depressing the key instantly

activates the LET mode, and the neon lamp goes

out. No actions are required to step the rotors

as there is no enciphering. What you type is what

you print.

Plain mode. The LET key

is connected directly to LET contact (4) of the

Shift tube circuit. Depressing the key instantly

activates the LET mode, and the neon lamp goes

out. No actions are required to step the rotors

as there is no enciphering. What you type is what

you print.

- Encipher mode.

The LET key enters the cipher unit as piggyback

letter V at the EV contact. Its enciphered

version exits the cipher unit at the DΔ contact and is

routed through the Letters Cam Switch to the Δ pulse coil to print

that letter. Since LET mode has a low threshold,

all high and low pulse coil letters are printed.

The timing shaft rotates, and at 10 degrees the

Letters Cam Switch changes connection to the LET

contact (4) of the Shift tube circuit. The neon

lamp goes out, but only acts as indication to the

operator. The machine itself stays in LET mode to

print ciphertext letters (see Shift Mode Switch).

- Decipher mode. The letter Δ, representing the enciphered letter V, is depressed and enters the cipher unit at the DΔ contact. The deciphered version exits the cipher unit at the EV contact as letter V and is routed through the Letters Cam Switch to the V key circuit (part of the V-SPACE coils pair). However, since logically the machine is currently in FIG mode with high threshold, the low pulse V is ignored, and the high pulse SPACE is printed. The timing shaft rotates, and at 10 degrees the Letters Cam Switch changes connection to the LET contact (4) of the Shift tube circuit. The machine is set to LET mode and the neon lamp goes out.

The reason for printing a space when deciphering the LET or FIG key instead of only changing the Shift mode is that activation of the Timing Unit is required for the timing signals and stepping of the rotors to correctly encipher or decipher the following letter.

The Pulse Signal generation and timing.

The timing signals for the electronics are generated in two different ways. When depressing a key, the corresponding pulse generator coil is grounded, causing a first pulse. This pulse is not generated by the pulse generator itself, but by the key at the moment he closes the circuit! While the key is still depressed, the pulse generator armature passes the grounded coil and induces a second pulse (which could be single or double) that initiates the print and rotor stepping cycle. On the right are the relevant parts of the circuit (see also the full circuit diagram).

The Pulse Generator coils' common (test point

V14) is connected through R131 and R114 to the +220

volts. Therefore, depressing any key connects its pulse

coil, which has low DC resistance, to the general commons

of all electronics. This causes a large voltage drop

across that pulse coil and the resulting

counter-electromotive force (CEMF) makes the pulse coils'

common negative to the general common of the electronics.

This negative pulse is the so-called "transient

pulse".

The Pulse Generator coils' common (test point

V14) is connected through R131 and R114 to the +220

volts. Therefore, depressing any key connects its pulse

coil, which has low DC resistance, to the general commons

of all electronics. This causes a large voltage drop

across that pulse coil and the resulting

counter-electromotive force (CEMF) makes the pulse coils'

common negative to the general common of the electronics.

This negative pulse is the so-called "transient

pulse".

The voltage drop on key closure is passed through R131, terminal X3 and C105 to the Gate tube B section's cathode, causing A section to cut off and B section to conduct. The Gate tube single-shot multivibrator is now triggered, but the voltage drop also discharged C116, causing terminal X1 to stay 10 milliseconds longer negative. Terminal X1 is connected to the Print tube's shield grid, thus preventing a little longer the Print Tube from firing.

The negative 10 volts transient pulse is also inverted by the transformer into a positive 30 volts and sent to the Sharpener tube. However, the processed pulse will not initiate printing because the Print tube's shield grid bias is still negative due to the 10 milliseconds delay at terminal X1. The transient pulse thus only initiated the multivibrator.

When the 10 ms delay has passed, and the key is still pressed down, the rotating pulse generator's armature will eventually pass the grounded pulse coil. This creates again a negative 10 volts pulse that enters the transformer (see direction i arrow) which in turn inverts the pulse into a +30 volts pulse and fires the Sharpener tube. This is the actual pulse of a letter or the initial pulse of an alpha-numeric double pulse.

Since the Print tube's shield grid bias is no longer negative, the Sharpener can now fire the Print tube. Note that after the pulse armature has passed the grounded coil, the decaying magnetic flux also induces a current in the opposite direction, but that pulse is blocked by the three diodes.

Firing the Print tube now energizes both the Printer Magnet to print the corresponding character and the Trip Magnet to rotate the Timing Unit that controls the cam switches. The Repeat Cam switch then cuts off the Gate tube A section's plate to prevent the multivibrator from completing a full cycle of pulse sensing, thus blocking stray pulses from the moving rotor's contacts in the Stepping Unit. More about the route of the signals through the rotors is found in the Sliding Contact Board section.

Cryptographic Properties

There are 2,821,109,907,456 ways to set 7 notch rings and 1 wide ring. There are 78,364,164,096 ways to set all core and notch combinations, relative to the machine. The alphabet ring, only a visual representation of the rotor positions, is disregarded. This gives the adversary a total of 1.90 x 1037 combinations, representing a 124 bit key.

Trying out all possible keys on a 124 bit key, a so-called brute-force attack, is considered infeasible with all present and future computer power. However, cryptanalysis is more than key size, theoretical security and brute-force attacks. Rotor cipher machines have proven vulnerable to certain types of cryptanalytic attacks, performed on fast computers. Therefore, the KL-7 is no longer considered secure. Nevertheless, even today, skilled cryptanalysts with current resources would still face a huge task to mount a successful attack against the KL-7, especially when they only have a limited number of messages at their disposal.

Encrypting a large number of messages with the same key always poses a risk, as there is more chance of messages being “in depth”, giving the cryptanalyst more statistical clues about that specific key setting. During the KL-7’s service time, the number of message, encrypted with the same key settings, was limited by compartmentalization. For a given day, instead of using one key list for all users, different key lists were distributed to different units, echelons, services, and geographical areas, also called crypto nets or radio nets, reducing the use of one specific key setting. An additional method to limit "in depth" messages is to encrypt each message with a unique random starting position of the rotors, called Message Rotor Alignment, explained in the message procedures below.

ADONIS and POLLUX Encipher and Decipher

Procedures

There were two types of operation for the KL-7, called POLLUX (1950) for low-level Army and Air Force traffic, and ADONIS (1951) for high-level traffic. The difference between them was the set of rotors and the method to determine the random starting position of the rotors for each new message, called Message Rotor Alignment.

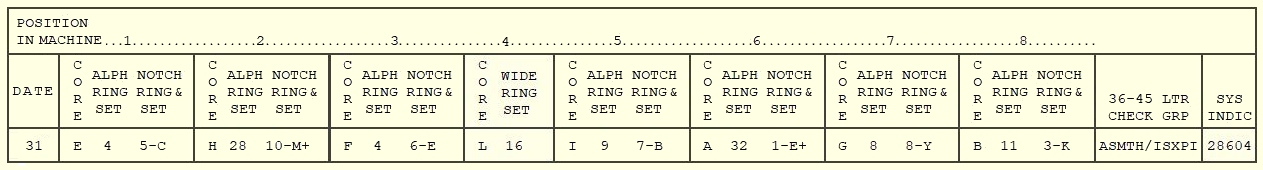

Each ADONIS rotor set consists of 12 (later 13) rotor cores, 11 notch rings and one stationary wide ring. Before using the KL-7, the internal settings must be set according to a key list that contains multiple keys, each valid for a period of 24 hours. Each daily key list determines the choice of rotor cores and its position in the cipher unit, the setting of its alphabet ring, and the type of notch ring and its setting on that rotor core. The rotor core that is selected for the fourth position must always be fitted with the stationary wide ring, which can also be set in any position on that rotor core. This wide ring prevents the fourth rotor from moving.

Below, the ADONIS key list example, in the format as documented in the declassified KAO-41C/TSEC. Usually, a second cipher unit, with the rotors arranged according to the key list of the previous day, was readily available. When they received a message from the previous day, the operator could quickly remove the current cipher unit from the rotor stepping unit and replace it with the old cipher unit.

Note: you can set the example key for day 31 on the KL-7 simulator and perform the encipher example shown below, to experience the encipher procedure as actually used by the operators. Be advised that the rotors of the simulator have their own core wirings because the secret wiring of the real rotors was never declassified, and the wiring of surviving rotors has been removed.

After placing all prepared rotors in the cipher unit, the new settings are checked with the 36-45 letters check. With the mode selector in Plain mode, all rotors are set in the “A” position. Next, the machine is set to Encipher mode (some rotors will move one step). The counter is reset, and the letter "L" is typed 45 times. The last two code groups should match the 36-45 letter check on the key list for that day.

The system indicator, shown at the bottom-right of the key for that day, consisted of five digits (ADONIS) or five letters (POLLUX) and was used before and after the enciphered message to identify the system and key.

For each new message, the operator must use new unique and completely random start positions for the rotors. The method to convey these rotor positions to the receiver is called the Indicator System. The random start positions, called Message Rotor Alignment, are visible through the little windows of the cipher unit and crucial for the security of the message because using the same Message Rotor Alignment for multiple messages leads to patterns that can be exploited by codebreakers.

To produce a Message Rotor Alignment, the operator takes a previously prepared random five-letter group called Message Indicator (see note further down). For our example message, we use the random message indicator "ELXNO".

1. Set the KL-7 mode selector to Plain

mode.

2. Set “AAA-AAAA” as rotor alignment with the

Set Key buttons on the front of the cipher unit.

3. Switch to Encipher mode (some rotors will move one

step)

4. Encipher the Message Indicator "ELXNO". The

resulting enciphered indicator will be "BHLDO".

5. Switch back to Plain mode.

6. Set "BHL-DOBH" as Message

Rotor Alignment by re-using the first two letters at the

end. Again use the seven Set Key buttons to adjust the

rotors.

7. Switch to Encipher mode (some rotors will move one

step), tear off the printed tape and reset the counter.

8. Encipher the example plaintext message "TOP

SECRET MESSAGE 123 TEST".

Any incomplete final group should be completed by one space and, if required, followed by enough random letters to complete that last code group.

Below, the resulting ciphertext. Note that if you enciphered the message with the KL-7 sim, the result might partly differ, depending on whether you switched to FIG and LET mode before or after the space.

|

The complete message includes the system indicator, the Message Indicator spelled-out (NATO alphabet), the enciphered text and repeated system indicator:

|

The standard format for enciphered messages was the so-called CODRESS, documented in the publication ACP 127 (unclassified). In such messages, the full originator, all addressees, and security classification were included in the enciphered text. These messages were always unclassified, although the coded groups contained secret information.

Below our example message with the priority pro-sign (here routine), routing indicator(s) of the addressee(s) and serial number, priority again with date and time group, groups count, and finally the message between two BT breaks.

|

The receiver has a KL-7 with the same rotor arrangement, as provided for that particular day in his key list. The system indicator “28604” in the received message identifies the ADONIS cryptosystem and key for this particular message. He will proceed as follows:

1. He switches his KL-7 mode selector

to Plain mode.

2. He sets "AAA-AAAA" as rotor alignment with

the Set Key buttons on the front of the cipher unit.

3. He switches to Encipher mode (not

Decipher mode!).

4. He enciphers the spelled-out message indicator

"ELXNO" to again produce the sender's original

Message Rotor Alignment "BHLDO".

5. He switches back to Plain mode.

6. He then sets "BHL-DOBH" as

Message Rotor Alignment, also repeating the first two

letters at the end.

7. He finally switches to Decipher mode and deciphers the